Automated Warehouse AS/RS System

In the realm of contemporary warehouse management, automated warehousing systems (AS/RS, Automated Storage/Retrieval System) have emerged as a pivotal technology to enhance both efficiency and precision. Chain We Machinery's AS/RS system maximizes storage space utilization, facilitates online equipment operation via computer control, and manages goods inflow and outflow with pinpoint accuracy. It maintains continuous inventory oversight to prevent the accumulation of outdated or surplus stock, thereby ensuring streamlined item handling and inventory control.

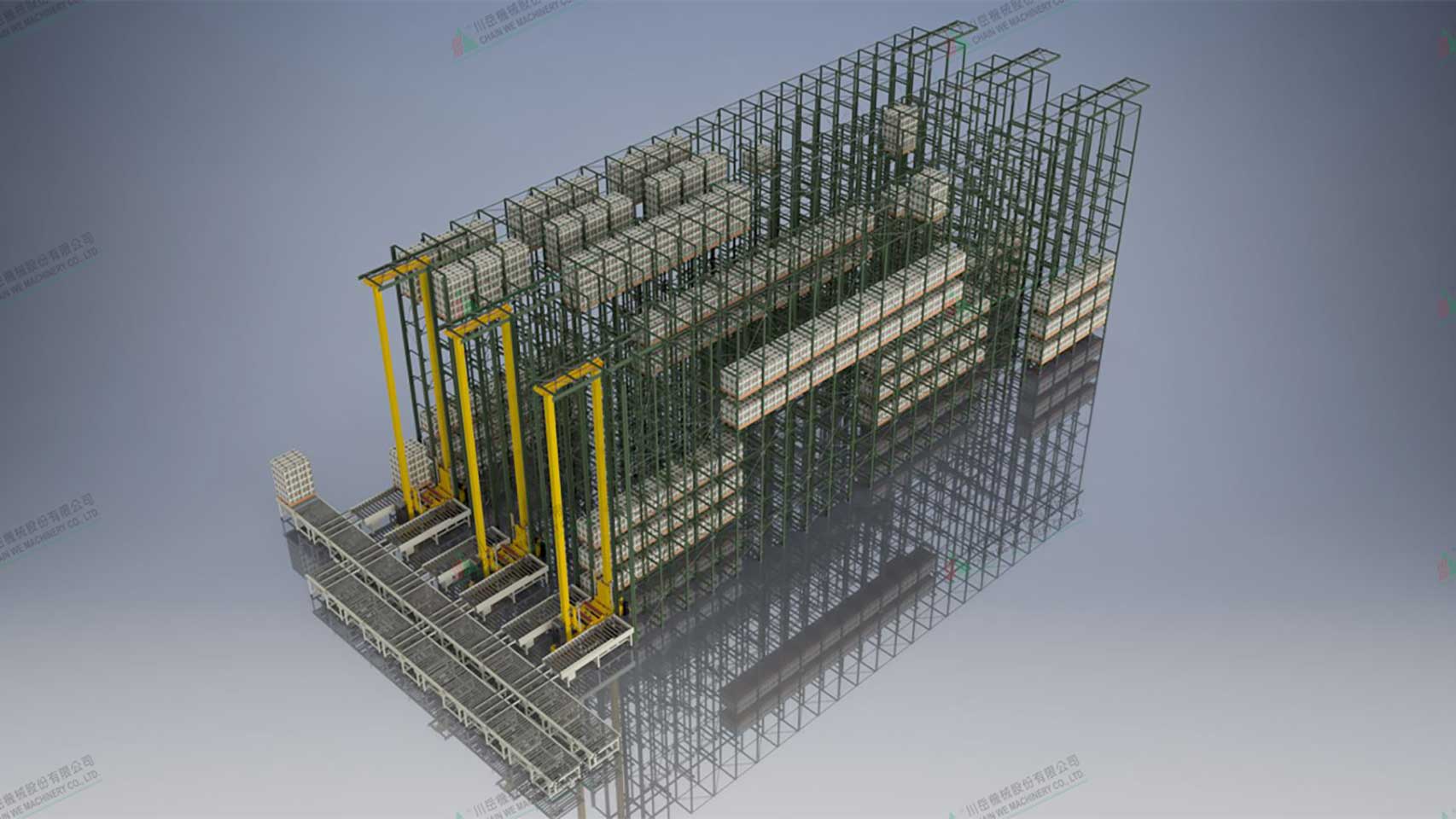

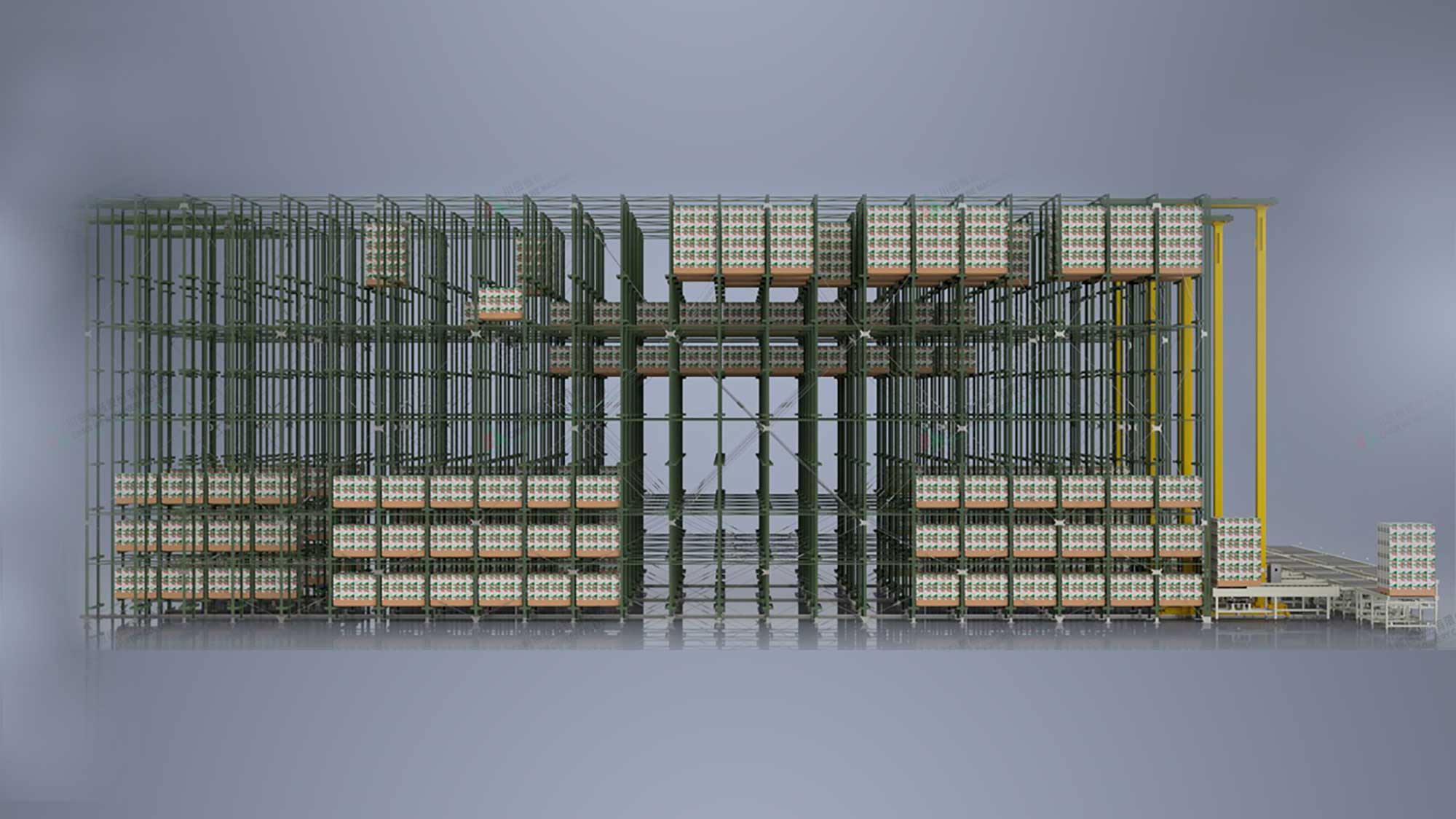

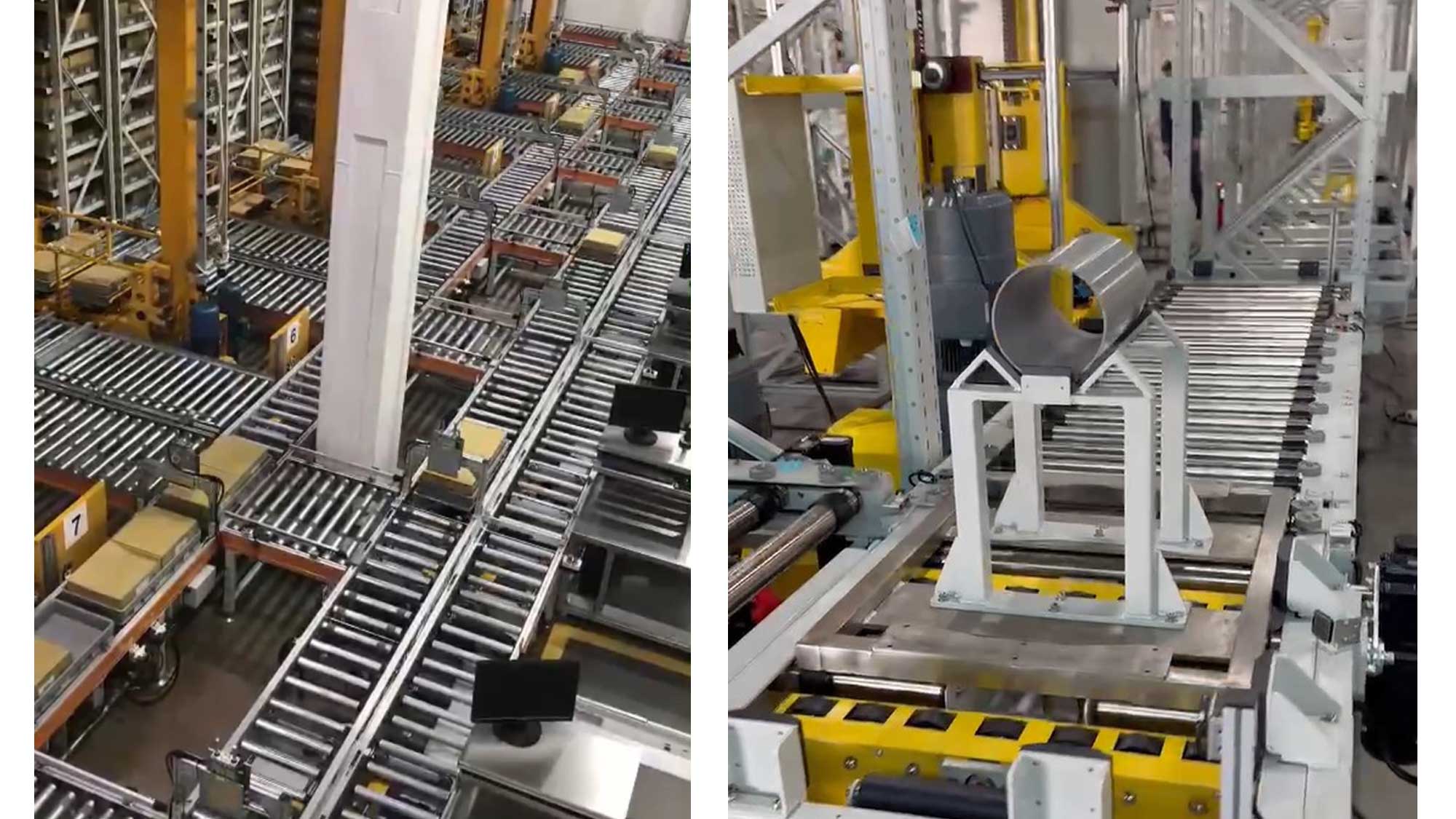

Chain We Machinery's ASRS system streamlines purchasing and storage workflows, enabling swift and precise item processing. Comprising towering three-dimensional racks, stacker cranes, a variety of forklifts, conveyance and retrieval mechanisms, autonomous vehicles, control systems, and ancillary equipment, it represents a comprehensive automated storage solution.

Chain We Machinery's automated storage solution achieves seamless automated restocking, delivery, and picking operations by amalgamating storage, transit, and sorting capabilities. The Warehouse Management System (WMS) takes full command of inventory oversight and item retrieval. This unified approach to information management smooths out the logistics center and production hub operations, substantially elevating operational productivity.

Chain We Machinery's ASRS system not only escalates the automation quotient of warehousing and logistics but also refines operational workflows and curtails labor demands. This savvy solution is adaptable to businesses of varying scales and requirements, thus bolstering overall storage efficiency and fostering advanced, high-performance logistics management.。

Opt for Chain We Machinery's automated warehousing system to inject unmatched operational efficacy and precision into your enterprise, propelling your logistics into a new echelon of smart management.